The Future of Fabric

Posted by Zoe on 8th Jul 2022

At Fabric Godmother, we always aim to stock a wide range of beautiful and interesting fabrics that you’ll be excited to sew with. Developments in fabric technology result in new fibres and production methods, and therefore products, coming through all the time. To keep abreast of what new things are available now, as well as what may be in the pipeline in the world of more-sustainable textiles, Josie, Phoebe and myself (Zoe) headed up to London last week to attend the Future Fabrics Expo. It’s organised by The Sustainable Angle, a non-profit organisation which aims to initiate and support projects with a focus on Sustainability in Fashion & Textiles.

All the products being presented at the expo claim to be more sustainable in some way, either through the raw materials they’re made from, the manufacture and/or finishing methods, or their degradability, and very often a combination of the above. The event gave Josie (the Fabric Godmother herself) and Phoebe (our assistant buyer) the opportunity to meet with lots of textile companies and discover what products they have on offer that might appeal to Fabric Godmother customers. In my role as sustainability coordinator, I took the opportunity to learn as much as I could from the educational displays.

So what did I discover? Well, it was really interesting to see how many options of ‘more sustainable’ fabrics are already on the market. Products that, as home sewers, we might have vaguely heard of, have very limited access to or that currently have a prohibitively high price point.

For example, there are textiles available from a number of companies including Bananatex that are made from the Abaca banana plant cultivated in the Philippines. The plant requires no pesticides, fertiliser or additional water, and is contributing to the reforestation of areas that have been eroded due to palm oil production. Below is a sample of banana plant fibre pre-processing:

Piñatex is a company doing something similar with pineapple plants, also grown in the Philippines which results in a product that resembles leather.

An Italian company called Orange Fiber is working with Tencel producers Lyocell to make fabrics that blend citrus by-products and wood pulp.

In the centre of the expo with a really interesting display highlighting a lot of super innovative projects. Some are already available to some degree but many of them are still very much in the R&D phase, and are most likely years away from being brought to market. There were a number of projects with garment fabric applications that are in the works that caught my eye in particular.

New York based company Ecovative is using mycelium, a root-like structure of fungus that usually lives underground, to grow materials with a number of exciting uses. It can be used to replace polystyrene in packaging, plus it can be used to make a natural, plastic-free alternative to leather. Using this substance could have heaps of environmental benefits, not least thanks to its biodegradability. I think mycelium is incredibly cool anyway, so I’m excited that its awesomeness may have a fashion application.

A company named Fulgar has developed a post-consumer waste yarn called Q-cycle that is made from old tires. So tires and other waste that cannot be recycled using mechanical methods, are broken down chemically into their component forms which display the same properties as virgin fossil fuels. These can then be used to produce a range of fabrics suitable for sports and activewear. I have been unable to discover if these fibres are being processed in a closed-loop system that reuses those chemicals, or how those chemicals are otherwise disposed of. But the reuse of worn tires that otherwise might be discarded is an interesting idea.

Another project that looked really intriguing by Dr Jess Redgrave (I have been unable to find a link) which looks at various applications of sunflowers for the fashion industry. Sunflowers can be grown as part of a regenerative farming system because they can be grown in various climates, can boost soil health and therefore improve biodiversity, plus sunflowers are drought resistant and can be grown without pesticides. Their potential applications for fashion include as an alternative cellulose fibre, in the production of water resistant coatings as a by-product from the sunflower oil industry, and as a source of pigment for natural dyeing. See below for some of the colours that can be produced from various parts of the plant.

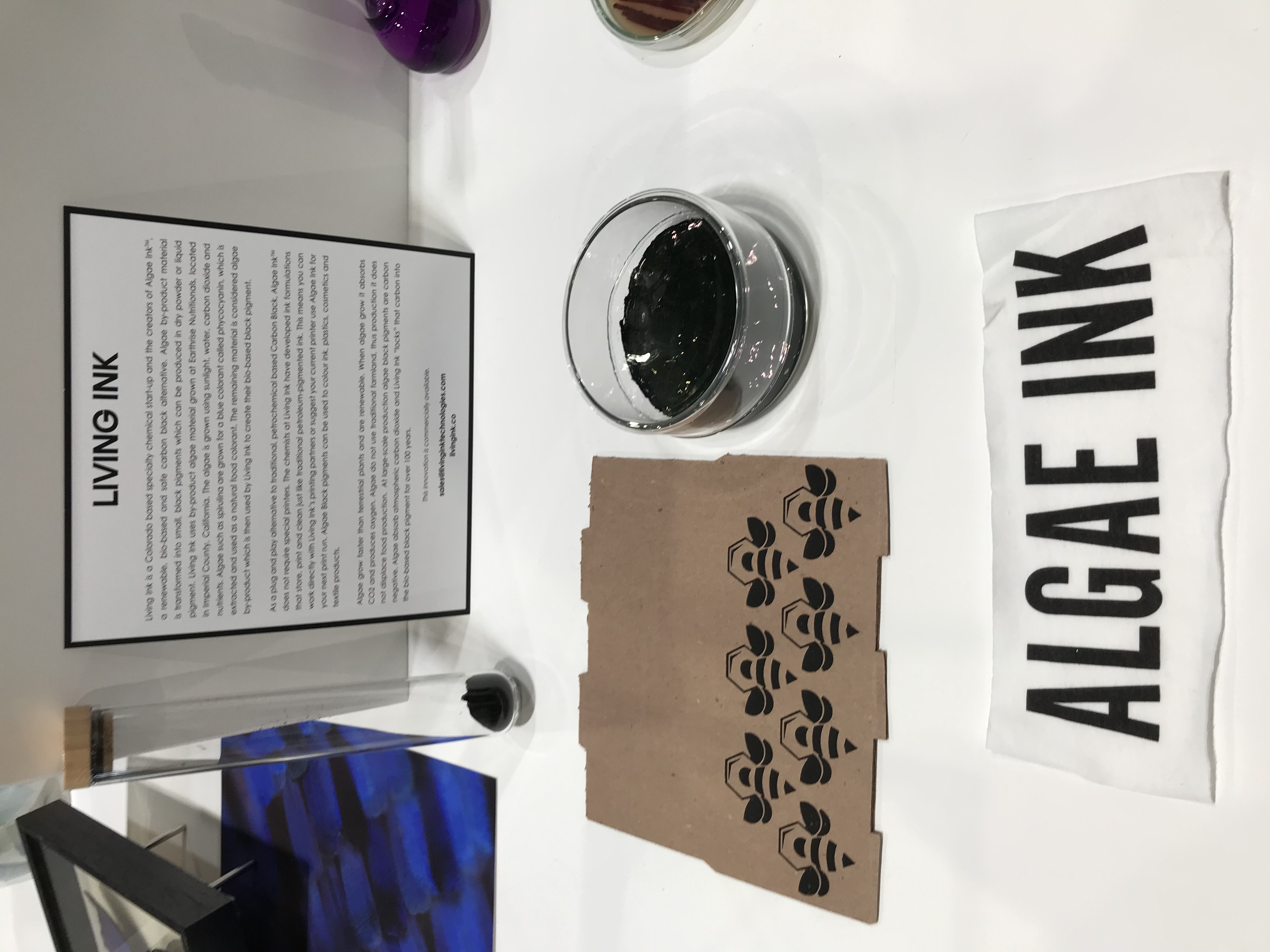

And one more project that definitely piqued my interest is an ink product that can be used in textile printing. These inks can replace traditional inks that are often derived from petrochemicals. This alternative ink is produced in the US using a by-product from algae production. Algae such as spirulina is already being used to make natural food colourants, and the by-product can be used to make pigments that can colour ink, plastics, cosmetics and textile products. Not only could this algae ink reduce reliance on petrochemicals used in traditional inks AND does not require any special printers, but the algae actually absorbed CO2 and locks it in, and releases oxygen. In fact, when it’s produced on a large scale it is actually carbon negative. Plus it doesn’t require farmland so won’t displace food production. So cool!

So based on what I saw, here are my predictions for fabrics relating to home sewing.

I do believe that in the not very distant future we’ll start to see a wider range of fabrics available for home sewing that encompass more aspects of sustainability. I think we’ll see interesting fibre sources more readily available and used in a wider range of fabric types. They’ll include banana, pineapple, citrus and milk fibres and possibly other agricultural by-products, most likely in blends with more traditional fibres including cotton. I predict that there will be a wider range of naturally-derived alternative leather options available than the current synthetic vegan leathers. I also think that at some point we’ll be able to offer fabrics that have been dyed using natural dye sources, with fewer chemical processes and less water usage. The continued development of mechanical and perhaps chemical fabric recycling processes will result in a wider range of 100% recycled fibre fabrics, and fabrics composed of a blend that includes recycled fibres.

If you’d like to learn more about how to sew more sustainably, you can find my podcast, Check Your Thread, wherever you find podcasts. You can also listen directly from my website, checkyourthread.com.